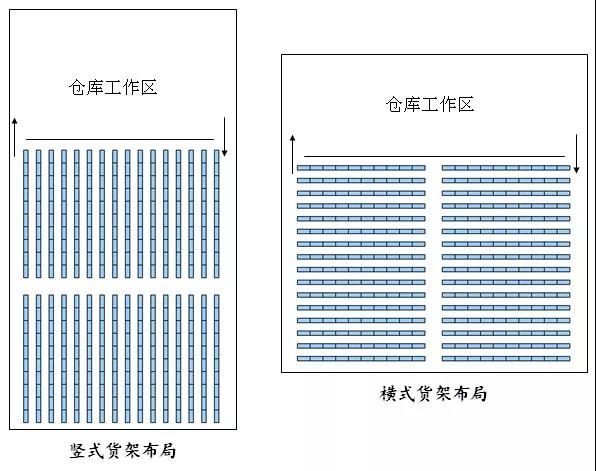

The definition of warehouse shelf layout given by Encyclopedia refers to the scientific planning and overall design of the number, scale, geographical location, warehouse facilities and roads of the warehouse in a certain area or reservoir area. So, what are the warehouse shelf layout and warehouse layout methods? According to the Qingdao shelf manufacturer, when we talk about the warehouse shelf layout in our life, there are only two common types: horizontal and vertical. The horizontal and vertical type is mainly for the warehouse working face and entry direction, as shown in the following figure:

No matter the horizontal or vertical shelf layout, the shelf length direction is perpendicular to the main road direction. Our common warehouse layout is generally the same. Why is there such a uniformity? First of all, let's analyze the design of e-commerce warehouse. Its idea comes from the design of traditional warehouse. For a traditional warehouse, as long as your warehouse is not round, the shelf or stacking position is vertical or parallel to the wall direction, which can make full use of space. When there is an angle between your shelf or stacking position and the wall, it is bound to cause a waste of plane space.

Therefore, in the traditional warehouse layout, in order to make full use of the warehouse space, the edge of the shelf or stacking position is vertical or parallel to the wall direction. But is this consideration absolutely correct in the warehouse layout of e-commerce? Or is it a better choice? I also thought so before, because everyone is doing this. Until I read an article on the design of warehouse shelves in foreign countries, I was deeply ashamed. I didn't think about the source of habits and the logic of that time for the things I used to do. Only then did I blind my vision and can't gain new knowledge.

Now, the editor of Qingdao shelf manufacturer recommends the two warehouse layouts mentioned in the article as follows: Compared with the following two layouts, the author of the foreign article tests that the efficiency of V-type shelf layout 1 is more than 11%, and that of V-type shelf layout 2 is more than 23%. So, how does the difference between efficiency improvement and efficiency improvement come about? The editor of Eurasian Group tried to make some explanations. At the same time, I also hope that some friends who are good at mathematics can explain it in terms of function theory.

Why is there such an adjustment to the traditional warehouse layout? Personally, I think the warehouse layout of e-commerce is a major factor in the consideration of picking efficiency. Traditional warehouses do not have high requirements for picking time and efficiency because of the low delivery frequency; However, the order processing characteristics of e-commerce determine its high requirements for the improvement of picking efficiency. In the case of small loss of warehouse area utilization, adjusting the warehouse shelf layout to improve picking efficiency will be a meaningful work that can be tried in warehouse management.

Qingdao Taiyue Metal Products Co., Ltd. is a professional manufacturer of storage shelving and racking, widely used in office, home, garage, shed, supermarket and so on. Let us help maximize storage space and keep your workspace organized!